Around 20 workers, including the owner of an East Burdwan-based factory in Kalna, have been seamlessly working for the last 48 hours in making intermediate jacking station (IJS) pipes for use in the rescue operation in the Uttarkashi tunnel collapse in which 41 workers are trapped since November 12.

Among the 41 trapped in Uttarakhand's Silkyara tunnel, three are from Bengal.

Soubhik Pakhira, 24, and Joydeb Pramanik, 18, both from two adjacent villages of Hooghly's Pursurah joined a private company last year and were posted at Silkyara tunnel construction site in Uttarkhand's Uttarkashi. The third trapped worker from Bengal, Manir Talukdar, 30, is from Cooch Behar.

The rescue operation that started on the day of the tunnel's collapse is going on.

Bilge Solutions, an expert in making IJS in the state, had been assigned to prepare two sets of IJS on short notice four days ago.

"It was a big task for us to prepare such important systems at such short notice. But when informed on the necessity (the rescue of 41 workers trapped in the collapsed tunnel in Uttarkashi), I immediately agreed," said Debansu Kumar, owner of the factory producing different these special pipes for engineering works and micro-tunneling project.

Intermediate jacking stations crucially bolster the support of pipes that penetrate the soil to create access to tough-to-reach places.

Kumar's factory has been assigned to build two sets of IJS, each eight-foot-long. The pipes and the system are made of concrete and metal.

One set of IJS was already sent on Wednesday, Kumar said on Thursday.

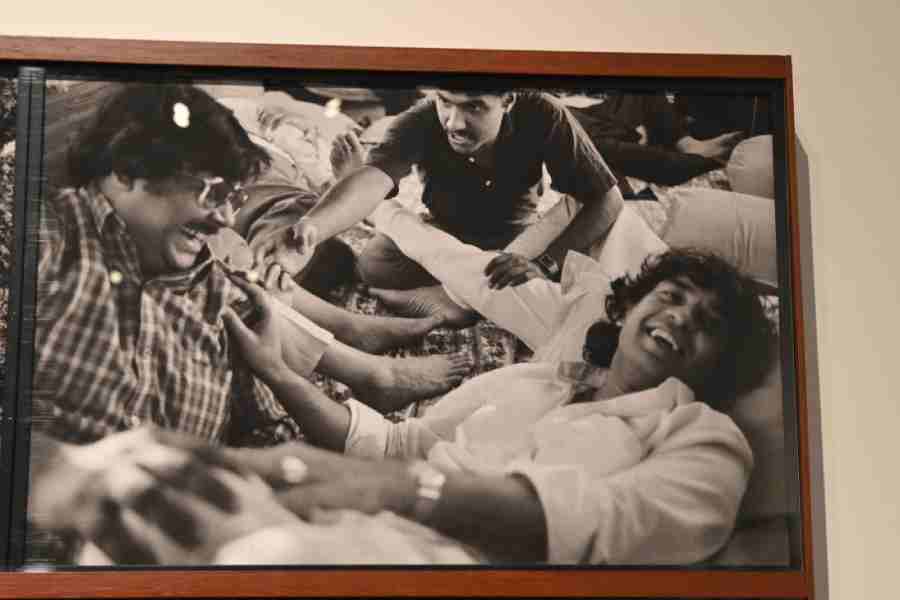

The team of around 20 workers is working 24/7 to complete the second set.

"As we had very little time in readying the assignment, we had to take the help of three more factories for different materials. DN Enterprise in Howrah is one of them. However, the credit should go to my colleagues in the factory who immediately agreed to work day and night after knowing the emergency in a bid to help speed up the ongoing rescue process," Kumar added.

Kumar's factory had last year got the experience of using IJS while working on a project to construct an underwater tunnel in neighbouring Assam's Bongaigaon.

Milan Guchhait, an engineer of the factory, and worker Paresh Konra, are among the 20 employees of the factory who have "not taken anything more than the minimum, basic breaks" for the last 48 hours in their efforts to finish the assignment as fast as possible, the factory owner added.

"We are all here working like a team. We are not worried about our rest right now. This is the time to serve the nation and save the lives of workers trapped for days in the Uttarkashi tunnel," said Guchhait.

Kumar said that he had agreed to plunge into the assignment "wholeheartedly and immediately" following only a telephonic conversation and was not even worried about payment issues.

"One of our known clients had called me up to place the order for the IJS sets and I never asked him for any purchasing order in writing. I only want that our seamless efforts help in the rescue of the 41 trapped persons," he said. "Our prayers are always with them."