Last summer, during my visit to India, I decided to spend a few days in Chennai. What caught my attention were long lines of local residents with jars and buckets waiting for drinking water from municipal water tankers. In summer months, tremendous groundwater depletion is common in Chennai, and water is brought to the city in tankers from Veeranam Lake, 250 kilometres away.

Ironically, the city is located on the coast of the Bay of Bengal, yet its 11 million residents are desperately thirsty. This immediately reminded me of recent protests in the streets of Khuzestan province of Iran, and long queues of people with containers fighting over water while waiting for the pipa in Mexico City; all resonating with the increasing water scarcity we are facing since the last few decades. All these places are very close to the sea, yet their inhabitants are miserably thirsty.

In late 1950, two chemical engineers — Srinivasa Sourirajan and Sidney Loeb of the University of California, Los Angeles — envisioned seawater to be a source of drinking water. The US Department of the Interior provided extensive funding for the research. Post-World War II there has been a remarkable advancement in polymer technology. Sourirajan and Loeb forced seawater at pressures about 70 times more than the atmospheric pressure across a thin film made of polymer.

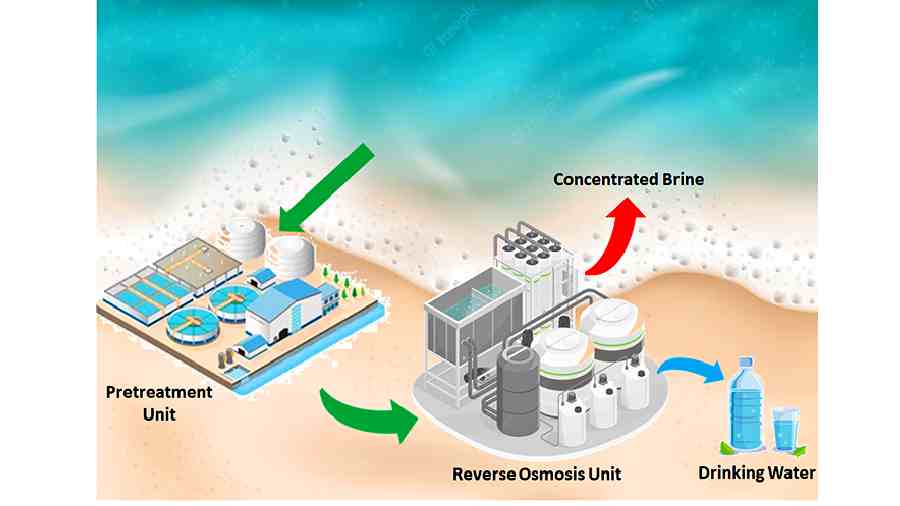

At these remarkably high pressures, smaller water molecules were pushed through the polymer films, leaving behind the slightly larger salt molecules. This technology required just pressure, higher than the seawater’s osmotic pressure, to maintain a steady flow of water through the film, producing clean water. This was the first demonstration of reverse osmosis (RO) technology; seawater desalination without involving any heat.

There is no other efficient way to remove salt from seawater, which contains 3.5 per cent salt.

After the first demonstration of RO in the early 1960s, the technology was not commercialised until the late-1980s. However, during this time, academic labs were thrilled by the new possibilities of RO and conducted pioneering work to understand the possible mechanism of how different polymer films can separate salt from water.

A breakthrough happened when John E. Cadotte and his coworkers at FilmTec Corporation (later acquired by DuPont) in Minneapolis, US, invented a technique of making very thin polyamide/nylon films (called membranes) by interfacial polymerisation. FT-30 by DuPont, which removes 99.9 per cent salt from seawater with a decent clean water production rate, remains the industry standard to date.

In the early 2010s, struggling with the extreme water crisis, many developing countries started taking an interest in RO technology to bring drinking water to their citizens. With a technology so mature and multiple instances of deployment on the west coast of the US, it seemed easy to transfer the knowledge elsewhere and set up RO plants. But it is not the case. Although the science was universally applicable, the deployment of the technology, be it the operation or scale, has to be tailor-made to specific geographic locations. Countries like Australia and Singapore picked up the problem early and deployed resources and research funding to tackle the issue, and are successfully operating RO plants for their drinking water needs.

the reverse osmosis process

As India gears up to deploy large-scale RO plants, it has several important concerns that need to be addressed for proper operation of these plants.

First, the quality of water the RO plants would treat to produce clean water is quite different from that in the US and Europe. There is a requirement for pretreatment plants before the water can be used by the RO system. There is ample room for improvement in this regard. A good membrane with high throughput is desirable for this purpose to remove larger impurities from water. Indigenous research in this aspect is needed and sufficient funding must be provided as a good pretreatment process prior to RO would make or break the whole plant’s efficiency. Even for the actual RO membrane, Indian companies need to mass produce a more economical alternative to FT-30 in the country.

Second, transporting clean drinking water to remote locations can be a hassle. Small-scale modular RO systems (maybe mobile) can be set up in remote locations such as the Sunderbans that utilise brackish water from local sources. This eliminates the need for transportation of potable water from RO facilities to remote places, maintaining the pristine produced water quality.

Finally, the use of renewable energy, especially from sources like solar or wind. This would reduce the carbon footprint of the RO process and can provide an effective way of utilising excess renewable energy that is produced during nonpeak usage hours.

This can also eliminate the need for sophisticated energy storage systems for these isolated power sources. Apart from this, special focus has to be given while discarding the highly saline unrecovered water so that it does not become an environmental issue.

I t has been established by many modern researchers that there is little scope for improvement for the actual RO membrane, as its peak performance has almost reached the theoretical limits. Much attention has to be given to, but not limited to, the concerns discussed above. From a beneficiary perspective, we also need to understand the energy penalty associated with water desalination and try our best to mitigate water wastage, starting from not using clean RO water for things such as cleaning or irrigation; a mistake which is quite common in the US. With a remarkably simple and mature science of membranes for RO, it is expected that developing countries can implement this technology for water crisis mitigation.

Sengupta is a research assistant at the Department of Chemical and Biological Engineering, University at Buffalo, US