It’s just another day in Foxconn’s 30-acre manufacturing facility dedicated to Xiaomi in Sri City (Chittoor district), Andhra Pradesh. As the bus pulls up, a small group of women greet the team of journalists while Muralikrishnan B (chief operating officer, Xiaomi India) and Josh Foulger (country head and managing director of Foxconn India) wait. Greetings exchanged, we discover that all the operators (save for a few male engineers) at the facility are women from all the districts of Andhra Pradesh. After a brief training period they hit the shop floor where every few months their training is evaluated, helping them move forward in the process chain.

If you have been impressed by the Redmi Note 8 Pro, t2 was even more impressed by the effort that goes into making the phone, during a walk-through of the plant. Before you get to hear the ever-popular Xiaomi ringtone, your phone passes through a number of tests from design stage to assembly line, including an ageing test, which takes eight hours. In fact, it takes around 24 hours before a phone is ready to be shipped to the company’s 10 warehouses in India.

After the walk-through, here’s what Muralikrishnan and Josh had to say about the quality of Xiaomi’s phones. By the way, the company has sold over 100 million smartphones in the last five years!

Challenges and solutions while designing for India

Muralikrishnan: Selling products in India is not easy. Obviously customers here are extremely demanding and if there are value champions in the world, the ones in India are really at the top of the list. Besides that, India is a country that has extremes of temperature and weather conditions. You have sweat, humidity, grime… you have the cold of the Delhi winter, the humidity of Chennai, the monsoons in Mumbai and the dust in Rajasthan. It’s super difficult to design products for such weather conditions but that obviously is a challenge we have taken up. The number one focus for Xiaomi as part of quality control is to design for India. You can’t fix things later. When you make products, you have to get it right at the design stage.

Let me share a few examples. P2i is a water-repellent technology (a nanocoating is applied to the exterior of the phone as well as some of the interior parts because there are orifices in way of ports. It changes the surface tension of water that falls on it, ensuring water droplets don’t adhere to the surface). The solution rose from a consumer feedback as well as the data we had — more number of customers were walking into our service centres during the monsoon months to complain about liquid-based damage to their phones. We introduced P2i.

Another example. Dust is everywhere and one part of the phone dust specifically hinders and gives trouble is the speaker. It settles on the mesh, disturbs the voice quality and it just becomes bad after a point in time. We recently launched an auto-cleansing speaker in Redmi Note 8. I am so impressed with our R&D team that came up with the solution. One solution could have involved taking a brush and cleaning it but that would damage the mesh. So we decided to emulate a specific soundwave at a specific frequency, which can push dust out of the speaker mesh.

Next, having rubber gaskets. Again, this has been done to stop water ingress. Our charging adaptors can withstand voltage fluctuations of up to 380V. There are more such features which we have introduced at the design stage to make products suitable for the Indian market. The USB cable that you see, there was a problem with the connector at the end… of it getting corroded, again a problem that arose because of humidity. So an anti-corrosive coating was given to stop the problem. All these have had a measurable impact in terms of customer satisfaction and a reduction in service centre and customer complaints.

Rock ’n’ roll devices

Muralikrishnan: All products go through some intense tests during the R&D stage when the initial prototypes of a phone are prepared. In the tumble test phones are tumbled for three hours. Then there is a ball drop test in which a ball is dropped on the phone for 14 hours. During bend test the phone is put in a denim pouch and a machine tries to bend it with a pressure of 100 Newtons. There is a climate shock test where temperatures range from minus 15° to plus 60°. Then comes key endurance tests during which a phone is switched on and off 10,000 times, USB cable goes in and out 10,000 times, fingerprint sensor is tested…. Once all these are certified during design stage there are additional tests during production. In the initial sample of a few hundred or few thousand units, some rigorous tests are done, like climate chamber test, freefall drop tests which happen in six different directions — front, back and each of the four corners. After all the tests we ensure all the functionalities of the phone are intact.

If there is one big lesson which I have learned while visiting factories is maintaining quality is not just about testing but also about the right process definition and defining the right standards, which is equally, if not more, critical.

Cosmetic inspection of battery

Cosmetic inspection of camera lens

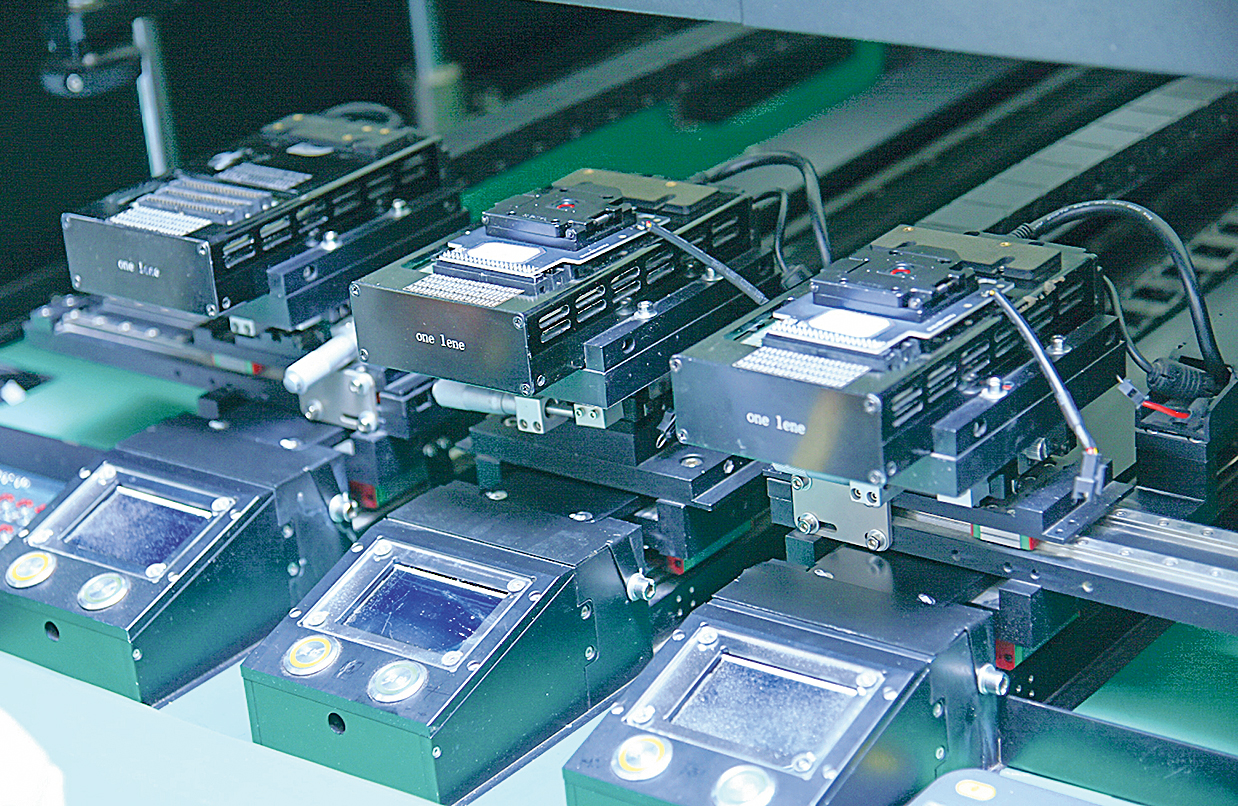

Camera lens test

Raw material aisle

Phones per second

Muralikrishnan: Overall Xiaomi, across all the facilities, has a capacity of three phones per second during operating months. Overall, of the 99 per cent of the phones that we sell in India are made in India. In case of some urgencies, like festivals, we might choose to import a very, very small quantity. And we do a very small amount of export to Bangladesh and Nepal. It’s a small amount.

(Top) Muralikrishnan B (chief operating officer, Xiaomi India) and Josh Foulger (country head and managing director of Foxconn India)

Women power

Josh: As you have seen, we employ a lot of women. So safety is very important to us and so is the work environment. The quality of work culture cannot be comprised. A lot of people working here come after hearing about us through word of mouth. We have never had a problem with people shortage. In this particular facility we have women from all the districts of Andhra Pradesh and associates also come from close to Odisha borders. We provide them accommodation, like a dorm but they are more like apartment blocks. People shouldn’t be travelling for two-odd hours. Beyond a certain distance we provide accommodation. I am happy that Xiaomi from day one have appreciated this initiative. When I came back to India in 2005, starting off with the Nokia factory, I didn’t know who to hire. My mom, who is a government school principal, suggested that I hire her girls. The idea started with that.

This 30-acre campus is about five years old. We started this campus for Xiaomi in 2015 and we had a very small start. One of the things we have learned along the way is in India there are no shortcuts. We are very happy that Xiaomi or our headquarters didn’t push us in that direction, in terms of bringing the right technology, of employing the right people. We have the most advanced technology here. All the assembly lines, all the machines are women-ed by women!

Today around 50 per cent of the women employees come from home and 50 per cent from dorms. The social implications have been more than what we had imagined. These ladies are time travellers. They wake up in a house, which at times has no running water, and then they come on buses that run on 40-50-year-old technology. Here is a factory, which is modern and they get exposed to world-class technology. Whatever you see here is best in the world. Like in Taiwan, Japan, Europe, China, US, Korea… the same technology is used here. They are trained to use technology.

Tackling water issues that face Chennai

Josh: When you run a supply chain operation like this, there are all kinds of challenges. I would say that not even one day was lost. We sourced water from different sources and were able to retain our operations. The rains have been okay this year and I am hoping that everything would be fine. The key is to be ready for anything when you are running manufacturing operations.

Survival of the fittest

When a new product is introduced, quality control starts at the R&D stage

1. Tumble test: 3 hours

2. Ball drop: 14 hours

3. Point pressure test: 3 hours

4. Extreme thermal test: -15° Celsius to 60° Celsius for nearly 20 hours

5. USB endurance test: 10,000 times

6. Headset endurance test: 5,000 times

7. Plus stress test: 8 hours

8. Key endurance test: Each key 50 million times

9. Fingerprint module key heat test: 60 million cycles

After a phone passes the NPI (new product introduction) stage, the device is brought for local manufacturing where a series of tests — also known as Mini Loop — are performed. Tests consists RF tests, climate chamber test, thermal shock chamber, free fall or drop test and vibration test. All devices are manually tested at three stages and all devices are automated tested at 10 stages. There is an ageing process of eight hours for all devices. Post-packaging, out-of-the-box audit is conducted by both Foxconn and Xiaomi both.