Princess and queens asking their beloved for fabric so fine that it would pass through their rings may be part of lore but the soft, light and almost transparent muslin, a handwoven fabric whose worth was once compared with gold, is gradually charting a revival after being virtually lost in the crowd of affordable machine-woven cloth.

Muslin or moslin is a fine handwoven delicate cloth, often considered a luxury fabric. The name originates from Mosul, a city in present-day Iraq. It was once widely believed that the fabric was developed from the city of its name but subsequent findings have confirmed that the fabric originated from the Dhaka region in present-day Bangladesh. Also known as Dhakai Muslin, it was recognised with a Geographical Identification (GI) tag in 2018.

A muslin weaver works on a loom

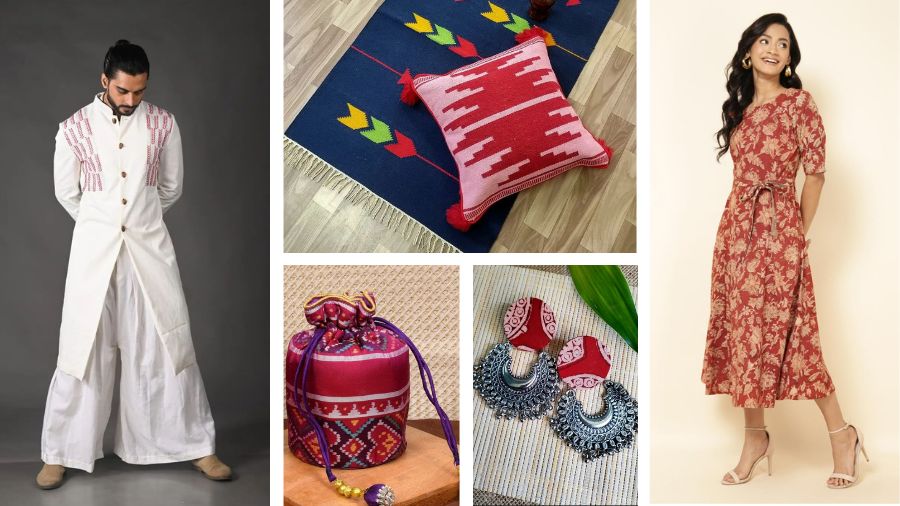

What better occasion than National Handloom Day — observed on August 7 — to call for the revival of muslin.

Through the decades, India’s handloom sector has a long history of cultural development.

What is muslin

The different varieties of thread used for different thread counts of weaving. (From left): 100, 200, 300, 350, 400, 450 and 500 thread count

Muslin refers to a specially handwoven cotton cloth known for its softness, lightness and transparency. It follows the plain-weave technique where the horizontal (weft) and vertical (warp) threads cross at right angles forming a simple criss-cross pattern. Each weft thread crosses the warp threads by going over one and then under the next and the process is repeated. Fine thread and high thread count were the unique features of muslin. The cloth is so fine that it was said that an entire sari made of muslin fabric could pass through a ring. Muslin was a valuable commodity and its value was often the same as gold. Muslin has found mention in the travelogues of famous travellers, including Marco Polo. By the 17th century, muslin was widely exported throughout Europe.

Downfall

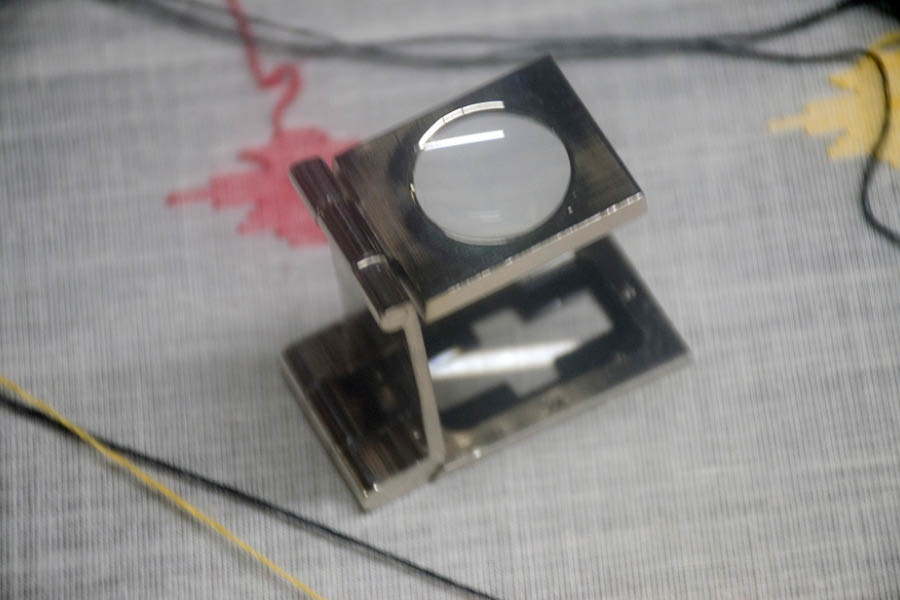

A thread counter is a simple optical instrument fitted with a lens used to finding the thread count

In the latter part of the 18th century, the British East India Company introduced mill-produced cloth in the sub-continent. These British-made fabrics were unable to compete with the locally produced muslin. The company administration introduced several policies to suppress the muslin industry. The weavers were prevented from weaving muslin and were forced to weave other fabrics. It is also said that the weavers who didn’t obey the British orders had their thumbs chopped off. This led to the decline of muslin. Over the years and decades, the process was lost.

Uses

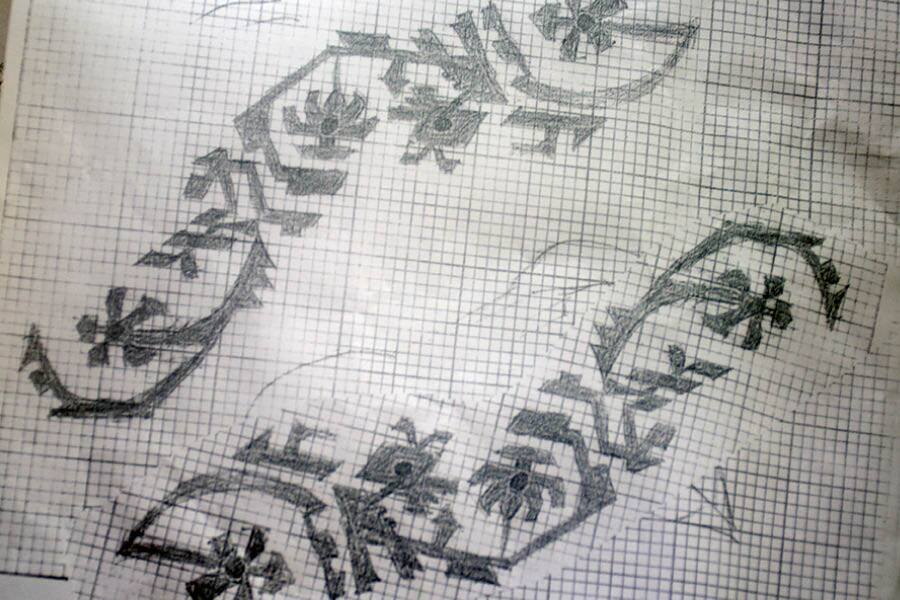

Designs drawn on graph paper

Apart from being the illusive fabric in the garment industry, muslin has a wide variety of industrial usage ranging from food and beverage to medicine. The fine cloth of muslin acts as filters in the juice and cheese-making industry. Surgical gauges used for dressing wounds are also made of muslin.

Revival

Designs been made on muslin sarees

In recent years, several steps have been taken to revive the lost art of weaving muslin in both Bangladesh and West Bengal (India). In West Bengal, the muslin revival has been an initiative of Khadi and Village Industries Commission (KVIC). At present, Ambika Kalna serves as the muslin hub of West Bengal. Ambika Kalna or simply Kalna is a famous temple town but unknown to many it also serves as an important textile hub for centuries.

Sukumar Das, one of the few weavers working on muslin, said: “Muslin requires special cotton and charka (spinning machine), fortunately both are supplied by KVIC. The looms are same but muslin requires special skilled weavers and the process is extremely slow and that is the main reason for the high cost of the fabric.”

“Fabrics with a thread count of 300 per inch or above can be considered as muslin and the thread count can go up to 500,” said Das, who runs a small shop in Ambika Kalna. “The price of muslin saris starts from Rs 30,000 and can go over a lakh. The price depends on the ornamentation, which is done manually by highly skilled weavers. The new generation is shifting away from saris, so we have started producing dupattas, which is much in demand among the new generation.”

The special ‘charkha’ used for making of the fine thread used in muslin fabric

Muslin versus Jamdani

Both have a Dhaka origin. Although both the words are used synonymously, they are not at all the same. Muslin refers to the fabric, and when elaborate designs are executed on the muslin it is transformed into a jamdani. Mondal says: “The designs are drawn on graph paper and supplied to the weavers who can execute it with great skill. But it is a lengthy process and obviously adds to the cost.”

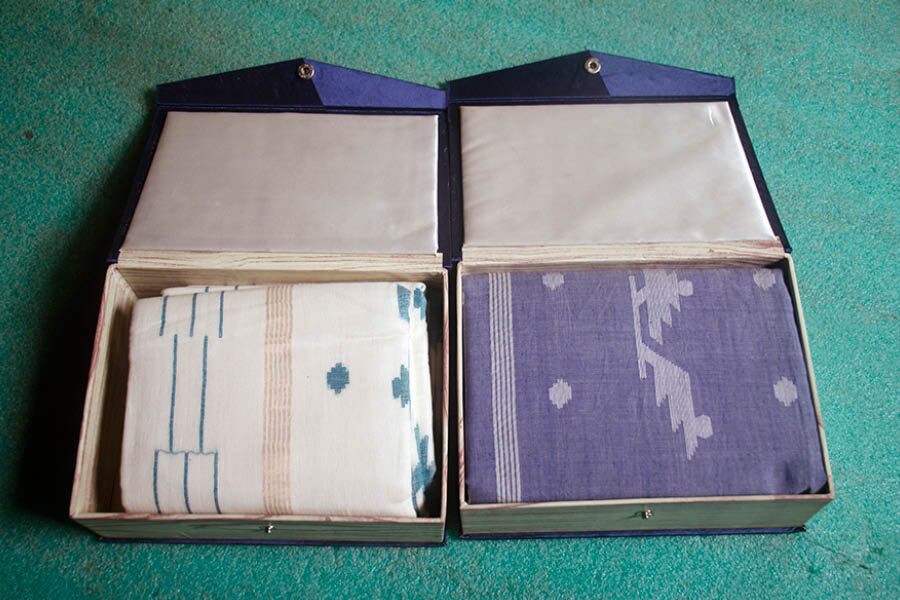

Muslin sarees are packaged in small cardboard boxes of approximate sizes of 8inches X 6inches X 2inches

A difficult road ahead

According to Das: “We have received a lot of help from the government but the products need to be sold but going by the high price, it is not an easy job. I have participated in fairs all over India and my sari has been purchased by famous Bollywood actress Hema Malini. But the overall sales in these fairs have always been low.”

Das further adds: “Pranab Mukherjee, the ex-President of India, used my muslin dhoti but these are isolated sales. We need to be linked directly to sellers and only bulk purchase can save the century-old art.”