The following is a fact sheet issued by the Centre for Science and Environment, a public interest research and advocacy organisation based in New Delhi, on the gas leak. The fact sheet is based on information available and assessment done till 3.30pm on Thursday.

What happened?

Styrene gas leaked at 2.30am on May 7 from a factory of LG Polymers India Pvt Ltd at Visakhapatnam in Andhra Pradesh.

What is styrene? How toxic is it?

Styrene is an organic compound used in the manufacture of polymers, plastic and resins. It is manufactured in petrochemical refineries. It is a likely carcinogenic substance. It can react with oxygen in the air to mutate into styrene dioxide which is more lethal.

According to the country’s manufacture, storage and import of hazardous chemical rules 1989, styrene is classified as a “hazardous and toxic chemical”.

Acute (short-term) exposure to styrene in humans results in mucous membrane and eye irritation and gastrointestinal effects. Chronic (long-term) exposure results in impacts on the central nervous system (CNS), leading to headaches, fatigue, weakness, depression, CNS dysfunction, hearing loss, and peripheral neuropathy. If the amount of styrene goes beyond 800ppm (parts per million), the person exposed to it can go into a coma.

The duration of the exposure and its relative concentration will determine toxicity. At 3pm, it was known that roughly 3 tonnes of the gas leaked from its storage tank and the feeding line.

In 2018, the factory had submitted a Rs 168-crore proposal to the Union ministry of environment, forest and climate change to expand its production capacity by another 250 tonnes per day (tpd) from the current 415 tpd. This permission, it is understood, has been recently granted.

“Styrene can stay in the air for weeks. It is highly reactive, it can combine with oxygen to form styrene dioxide which is more lethal. The presence of other pollutants can also affect the reactivity. On a sudden note operating one reactor in full load can also lead to such disasters,” says Thava Palanisami, professor, Global Centre for Environmental Remediation (GCER) & CRC for Contamination Assessment and Remediation of the Environment (CRC CARE), University of Newcastle, Australia.

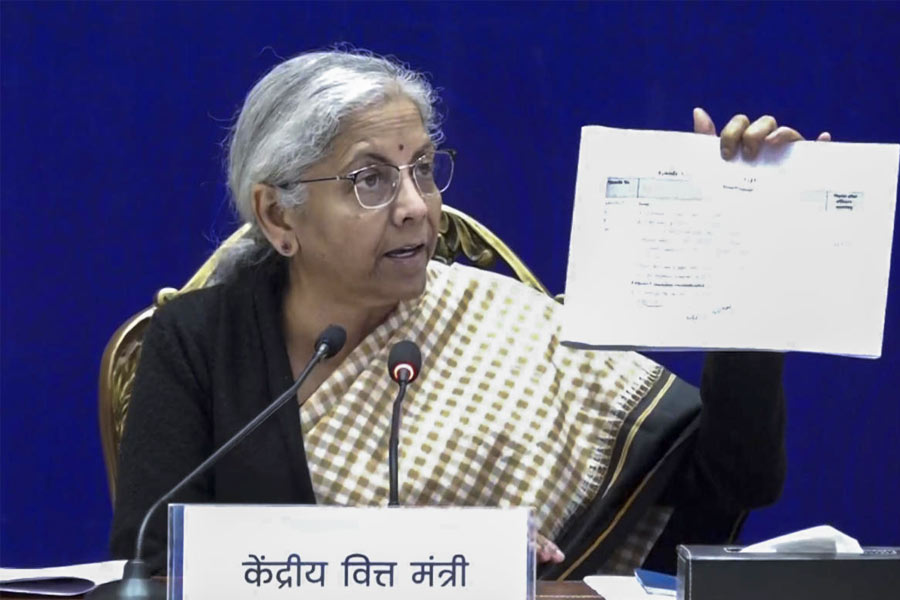

A father rushes to take his child for treatment. (PTI)

How did the disaster happen?

Styrene monomer was being used at the manufacturing plant to produce expandable plastics. The storage requirement of styrene monomer says that it should be stored strictly at a temperature below 17° Celsius.

There was a temporary partial shutdown of the plant owing to the Covid pandemic, excluding maintenance activities in the plant, which were being carried out as per a pre-determined schedule. The problem began as a result of styrene gas not being stored at the appropriate temperature. This caused pressure to build up in the storage chamber and led the valve to break, resulting in the gas leak.

Also, the container that was being used to store styrene gas was old and not properly maintained. This non-maintenance of the facility resulted in the leak of 3 tonnes of styrene into the surrounding areas.

Another issue was the defunct VOC detection system at the plant; there is no monitoring mechanism that was installed to specifically detect styrene. The facility is spread over 600 acres, including the nearby residential areas (according to terms of reference submitted by the company in 2018, it is spread over 231 acres). The impact zone has been in the range of 2-3 km. There is a revenue village nearby and the facility is surrounded by residential areas, resulting in a higher rate of exposure.

What is the immediate treatment?

The most important immediate treatment is to give oxygen to the affected people. The people in the zone also need to be evacuated as long-term exposure can be detrimental to their health. Also, as styrene reacts to form styrene dioxide, the air could remain contaminated for some time. However, the winds blowing from the sea could also help to disperse the gas.

The Public Liability Insurance Act of 1991 imposes a no-fault liability on the owner of hazardous substance and requires the owner to compensate victims of accident irrespective of any neglect or default. For this, the owner is required to take out an insurance policy covering potential liability from any accident.

There are clear rules on hazardous chemical storage under the EPA, 1986.The unit in question is an ISO-certified facility, which means it has a protocol for everything.

What should be focus area of a probe?

It needs to be investigated whether the plant management, in its haste to re-start the plant, ignored the protocol of doing maintenance of the plant before resuming operations. Whether proper storage of the gas — maintenance at the temperature required — was undertaken and whether fixtures were fault-proof should also be investigated. (This question has been added by this newspaper.)

What is the lesson for the Covid season?

The leak could be just a tip of the iceberg. This shows us that there are ticking bombs out there as the lockdown ends and industries start resuming activities. Therefore, an immediate directive must go to all units to ensure safety while resuming operations. In case the lockdown continues, these safety precautions must not be negated.