A gas leak in the dead of night at a chemical plant that was emerging from the Covid-19 lockdown killed at least 11 people and left hundreds in hospitals in Visakhapatnam on Thursday.

Terrifying accounts of people collapsing all of a sudden poured in while the country is in the middle of the fight against the virus outbreak and underscored the need for taking extra precautions when industries reboot after a long freeze.

The tragedy rekindled memories of the 1984 Bhopal gas disaster but doctors said they expect no long-term health consequences on survivors at the east coast city in Andhra Pradesh.

The accident occurred some 14km inland from the coast at a plant operated by LG Polymers, a unit of South Korea’s biggest petrochemical maker, LG Chem Ltd.

The company spokesman said production at the plant had been suspended because of India’s nationwide lockdown to stop the spread of the coronavirus outbreak, but it was preparing to resume operations, Reuters reported.

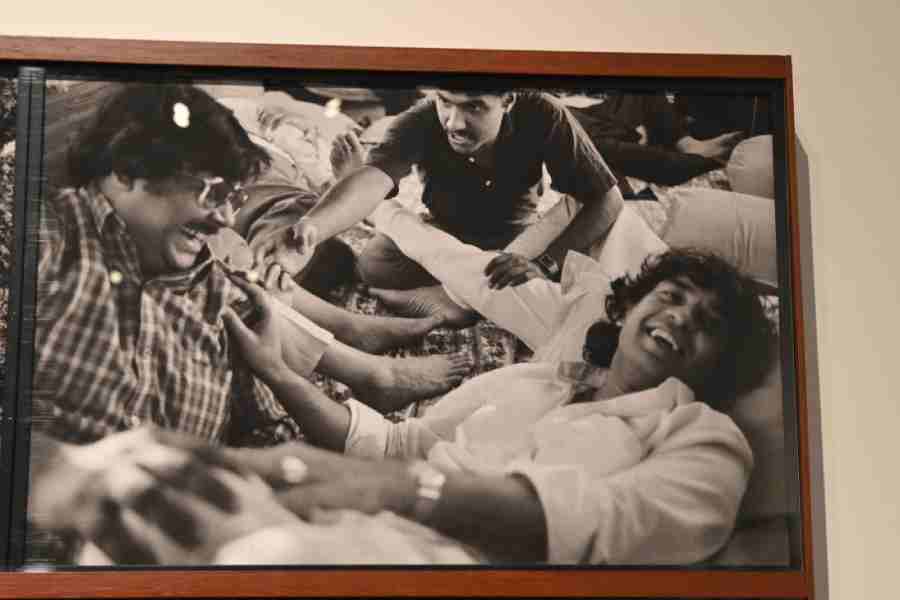

A number of victims collapsed and lay unconscious on the streetside as volunteers fanned them and others carried them to ambulances. Among the dead were two children — aged six and nine — a first-year medical student and two people who fell into a well while fleeing the vapours from the plant.

Srijana Gummalla, commissioner of the Greater Visakhapatnam Municipal Corporation, said gas from styrene, a principal raw material at the plant, leaked during the early hours of the morning, when families in the surrounding villages were asleep.

The leak started around 3am. Yashwanth Saikumar Ambati, 23, who lives about 300 metres away from the plant, said he woke up around 4.30am because of a strong smell. “I went back to sleep and I woke up around 6 because the smell got stronger. My eyes were itchy, and I was feeling drowsy, light-headed and slightly breathless,” he told Reuters.

Narendra, another resident, said he saw many people slowly losing their strength and falling unconscious.

“We’ve received reports of 11 deaths and between 20 and 25 people are critical,” S.N. Pradhan, the director-general of the National Disaster Response Force (NDRF), said in New Delhi.

Emergency teams from the NDRF had scrambled to the site and, working with the local police and fire departments, evacuated around 500 people, including children, from an area within a 3km radius of the factory, Pradhan said.

Footage shows a woman falling when she tried to sit after the gas leak at Venkatapuram village, where the LG Polymers plant is located, in Visakhapatnam on Thursday. (PTI picture)

The health effects of styrene depend on the amount and the site of exposure, a senior pulmonary medicine specialist said. “It can affect the throat and airways, the skin or the eyes,” said Randeep Guleria, director of the All India Institute of Medical Sciences, New Delhi.

Those who have died were likely exposed to large amounts of the gas.

A glitch in the refrigeration unit attached to the two styrene tanks at the chemical plant caused the vapour leak, district collector V. Vinay Chand said, quoting a preliminary report.

The leak was so intense that “only around 9.30am, could we understand what exactly it was as the thick fog that formed in the area cleared”, the collector said.

“Styrene monomer is normally in a liquid state and is safe below a temperature of 20 degrees Celsius. But because of the malfunctioning of the refrigeration unit, the chemical started gasifying,” he said.

The glitch caused the temperature in the chemical storage tank to rise above the safety level of 20 degrees, leading to gasification and consequent evaporation of styrene.

The plant had two tanks of 3,500 kilo litres and 2,500 kilo litres capacity, and the leak occurred in the 2,500kl tank. At the time of incident, it had 1,800kl of the chemical.

After the leak, the gas spread to the surrounding villages. Venkatapuram, where the plant is located, is the “predominantly worst affected”, the collector said.

It could take 12 to 24 hours to bring the vapour to zero level, Chand said.

The non-government Centre for Science and Environment (CSE) said on the basis of information available at 3.30pm on Thursday that the leak likely occurred because styrene gas had not been stored at the appropriate temperature.

“This shows us that there are ticking bombs out there as the lockdown ends and industries start resuming activities. Therefore, an immediate directive must go to all units to ensure safety while resuming operations,” the CSE said.

Additional reporting from PTI and Reuters