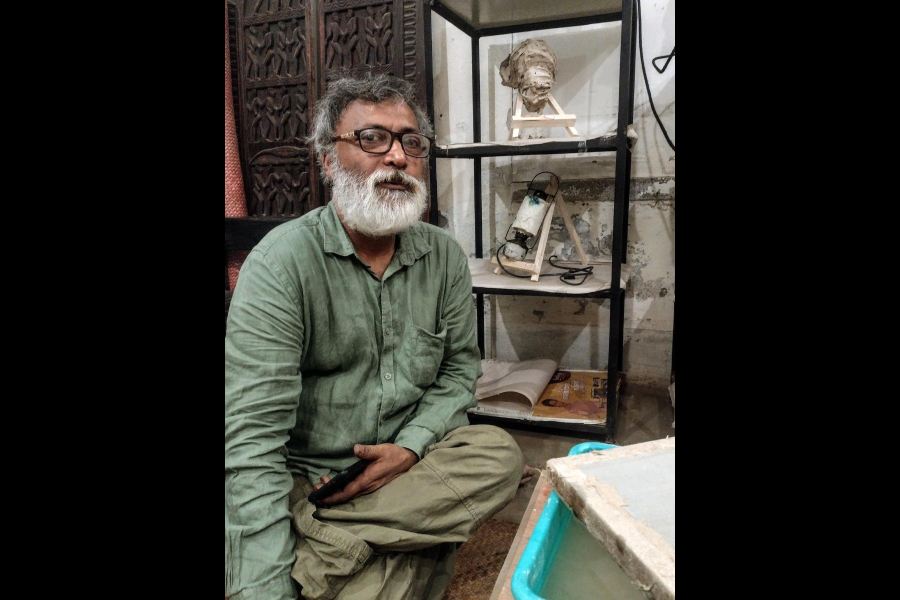

Barun Chatterjee, 52 years old and holder of a PhD degree in Bengali literature, lives in a wide-verandahed house in a village called Chella near Bolpur town in Birbhum. At any given time, the verandah is festooned with drying sheets of handmade paper of various sizes, textures and colours. There is the brown of the unbleached paper made of straw, the white of the tensile paper made from the banana plant and the thick, off-white paper made from sugarcane waste. These are just some of the things Chatterjee makes paper from.

The raw materials are harves-ted, processed and formed into paper by hand. Yes, harvested too, because, unlike other paper-makers, Chatterjee grows his own raw materials — paddy, sugarcane and, recently, mulberry. He even has a bed of papyrus plants that are descended from plants that came all the way from Egypt. Chatterjee came to know of an NGO that donated papyrus plants all over the world and they were more than happy to send him some.

“India has a long history of paper-making,” says Chatterjee. It was a completely indigenous method, not learnt from either the Chinese or the British. This method of making paper from pat, or the jute plant, lost out to the methods imported by the colonisers. “In the late 19th century, the best quality paper was made in Patna jail,” he says. The British tutored the inmates and this was, apparently, the first instance of large-scale paper manufacturing in India; whatever was produced was exported.

He is a fountainhead of know-ledge on the subject because that is his latest subject of research — he plans to start a magazine called Kagaj documenting the history of paper-making in India. He intends to print it on the acid-free, organic paper he makes.

Chatterjee used to teach Bengali literature at Malda College and later at Calcutta’s Vidyasagar Evening College but quit to concentrate on research. He says, “My father bequeathed to me the papers of my grandfather, who was a doctor. Among them were not only his diaries, wherein he kept a meticulous record of the diseases and patients he treated, but also the letters that patients or their family members had written to him, either asking for his suggestions or telling him that the treatment had worked.” As he studied the papers, Chatterjee was fascinated by the information within. “From literature, I went on to the study of ephemera,” he says.

Unfortunately, the ephemera Chatterjee inherited was ready to disintegrate at the flick of a careless finger. Before he completed his study of them he needed a way to preserve and restore them.

Chatterjee has a lifelong lovefor books — his home still over-flows with them — so it was natural that he would have ties with the venerable library of his hometown, the Uttarpara Jaykrishna Public Library. This library houses some of the oldest periodicals ever published in India.

During Chatterjee’s youth, there was an attempt made to preserve and restore them. Chatterjee’s first impulse was to take his grandfather’s papers to these restorers, but then it occurred to him that they would not be possessed of the requisite expertise. “The very first tenet of restoration is that you should be able to undo any changes you have made so that when a better technique of restoration is found, it can be used on the books,” says Chatterjee. Unfortunately, that wasn’t what was done in the caseof the Uttarpara library with theresult that the restored books are now unreadable.

Chatterjee was exposed to world-class restoration techniques during a trip to Israel, where he learnt that the one thing absolutely necessary was a special type of handmade paper found in Japan. Washi is made from kozo or paper mulberry. Also called kozogami, it is a nearly transparent, acid-free tissue paper that is also very strong. It is used along with a chemical-free glue to restore frayed pages and it can be removed if needed simply by dampening it. Unfortunately, it is also very rare and expensive. Chatterjee wondered if it could be replicated using easily available raw materials in India.

To that end, in 2017, he went to Pondicherry to learn paper- making from a French couple who live in Auroville. About a year later, he had built his house in Chella and was practising his craft. “I moved here because I needed space and because Birbhum was close to my heart. I had spent my childhood here,” explains Chatterjee. He planned to grow his own raw materials and he needed people with knowledge of farming. Chella gave him Khokon Bar, a Sriniketan graduate who is Chatterjee’s right hand. “I couldn’t have achieved what I have without Khokon,” he acknowledges.

While paddy is the most common crop in Birbhum, it was of no use because the hybrid variety grown is too short. “The straw was not long enough for paper-making,” explains Chatterjee. The quality of paper depends on the length of fibre used, the longer the fibre the better the paper. To get the right quality of straw, Chatterjee grows gobindobhog and wild rice. Later, he started growing sugarcane.

Ironically, the first earnings Chatterjee saw from his craft came from the sale of its byproducts — gobindobhog packaged beautifully in cane baskets and gur packaged in terracotta jars. While thinking about how to attractively package the products in biodegradable material, Chatterjee realised that the paper he is currently making would be perfect for packaging. “While it is a far cry from the washi-like paper I am working towards, the paper I make now is thick and strong,” says Chatterjee. He is in touch with various people to take his plan forward.

In the meantime, he has another idea — a recipe for that elusive restoration paper involving tootor mulberry.