The Netherlands operation of Tata Steel’s European business hit its highest ever profit after tax (PAT) since its acquisition by the Indian company, in a year it got decoupled from the British unit.

Tata Steel UK and Tata Steel Netherlands will now act as independent units and pursue their own strategic paths after operating together under one entity, even before Tata Steel acquired Corus Group Plc, later renamed Tata Steel Europe, in 2007.

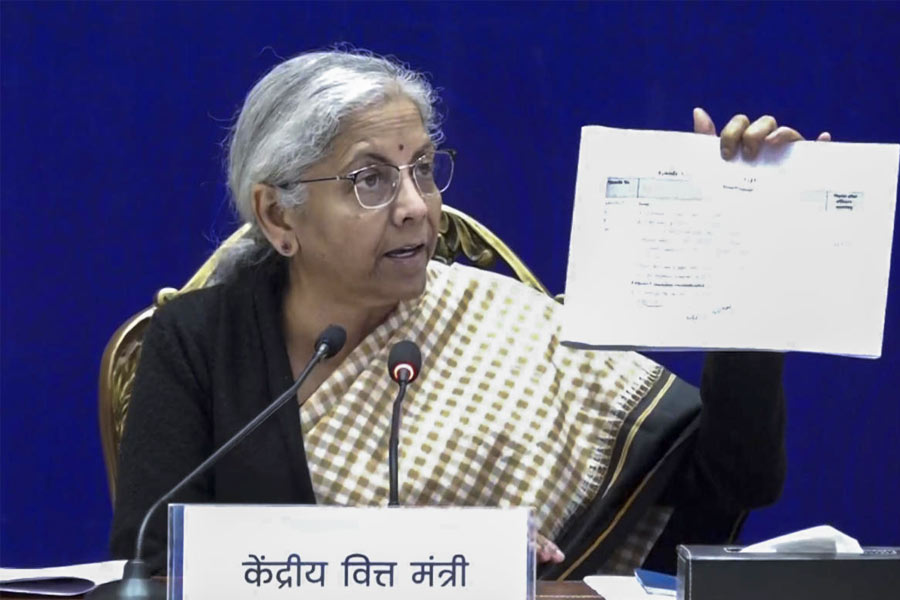

“In Europe, Tata Steel achieved a complete separation of its UK and Netherlands operations in October 2021. Under the new structure, Tata Steel UK and Tata Steel Netherlands will operate as two independent companies pursuing separate strategic paths,” Natarajan Chandrasekaran, chairman of Tata Steel, said in his address to the shareholders in the latest annual report of the company.

The profit after tax before exceptional items for Tata Steel Europe, which includes both the UK and Netherlands units, stood at Rs 9,235 crore in 2021-22 compared with a loss of Rs 6,155 crore in the previous fiscal. This is the best financial performance since the acquisition in 2007 on an operational basis.

Much of it was accounted for by the Netherland business which is primarily located in the port city of IJmuiden. The installed capacity of the Dutch plant is 7 million tonnes (mt) in contrast to the 5mt capacity at Port Talbot, the primary location for Tata Steel UK.

In the year gone by, Tata Steel Netherlands produced 6.6mt of liquid steel and TSUK’s Port Talbot turned in 3.5mt of liquid steel.

Even though the separation of the businesses was complete from October 1, the company did not provide profit and loss separately this year. However, it is understood that the Netherlands business accounted for over two-thirds of the profit for TSE.

While Chandrasekaran’s comment on pursuing separate strategic paths opens up many possibilities — the Indian parent was trying to sell the Netherlands business to Swedish steelmaker SSAB before the pandemic — it appears for now that the Dutch business will be on the path of a greener future ahead of the UK unit.

During the year, Tata Steel announced plans to pursue a fully sustainable future for its steelworks in IJmuiden by adopting a hydrogen route using the direct reduced iron (DRI) technology that makes iron using natural gas or hydrogen before it is converted to steel in one or more electric furnaces.

TSE is pursuing its ambition for IJmuiden to reduce CO2 emissions by 5mt a year by 2030. It has been exploring various technological options, including the capture and storage of CO2 or a hydrogen route.

With the announcement, the company is undertaking a detailed assessment of the hydrogen route in IJmuiden and is in discussions with all stakeholders involved to further develop this route.

In comparison, Tata Steel continues to have discussions with the UK government for support to transition to low-carbon steelmaking, which is to secure a long- term sustainable future for the business in Port Talbot.